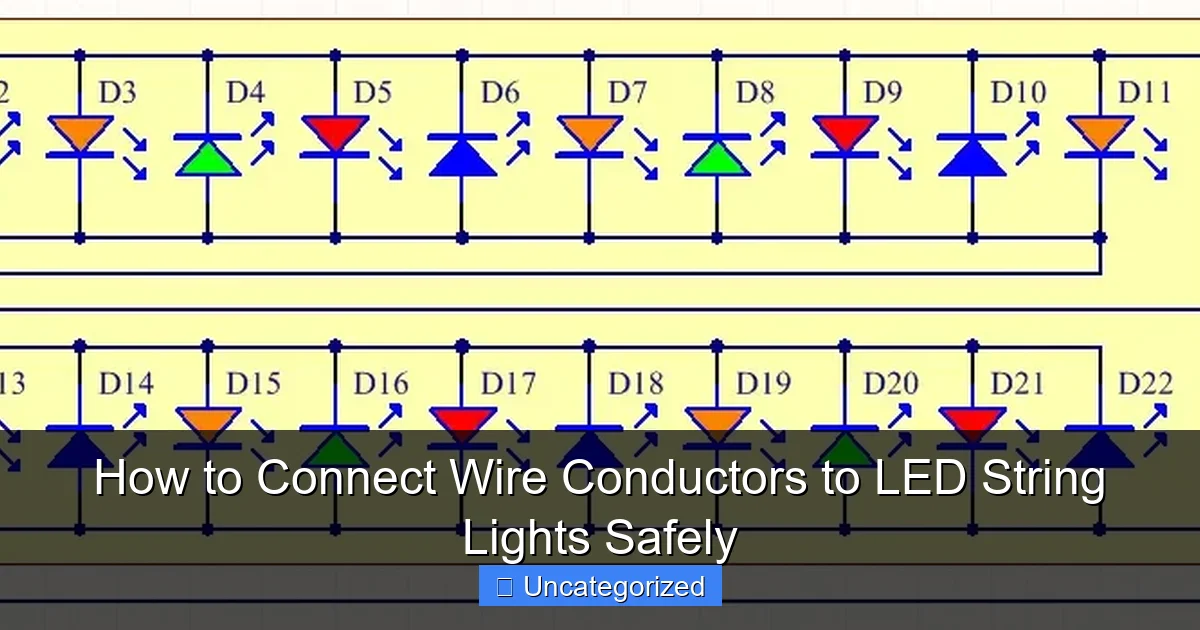

Featured image for how to connect wire conductors to led string lights

Image source: i1.wp.com

Always disconnect power before connecting wire conductors to LED string lights to prevent electrical shock or short circuits. Strip, align, and securely solder or use waterproof connectors for a durable, safe link—never twist wires loosely. Ensure all connections are insulated and tested before powering on.

“`html

How to Connect Wire Conductors to LED String Lights Safely

Key Takeaways

- Strip wires cleanly: Use a wire stripper to expose 1/2 inch of conductor for secure connections.

- Twist and solder: Solder wire leads to LED terminals to prevent loose or intermittent connections.

- Heat-shrink tubing: Insulate connections with heat-shrink tubing to avoid short circuits and corrosion.

- Test before sealing: Power the lights briefly to confirm polarity and function before finalizing the connection.

- Secure connections: Use zip ties or clips to relieve strain on soldered joints and prevent damage.

- Follow polarity: Match positive to positive and negative to negative to avoid damaging LEDs.

Why This Matters / Understanding the Problem

Ever tried setting up LED string lights for a party, only to realize one strand isn’t working because of a loose wire connection? Or worse—noticed a spark when plugging them in? These issues often stem from improper wiring. Learning how to connect wire conductors to LED string lights safely isn’t just about aesthetics—it’s about avoiding fire hazards, electrical shorts, and wasted money on damaged lights.

Whether you’re extending a string light setup for your patio, fixing a broken section, or creating a custom lighting design, connecting wires properly ensures your LEDs shine bright and last longer. Many DIYers overlook basic electrical safety, leading to flickering lights, melted insulation, or even blown fuses. The good news? With the right tools and a clear method, you can do this safely at home—no electrician degree required.

Understanding the basics of conductor types (solid vs. stranded), polarity, and insulation protection is key. This guide walks you through every step, from prep to testing, using real-life scenarios like fixing a cut power cord or adding a second string. By the end, you’ll not only know how to connect wire conductors to LED string lights safely, but you’ll also avoid the most common (and dangerous) mistakes.

What You Need

Before starting, gather these tools and materials. Having everything ready saves time and prevents mid-project trips to the store. Here’s what you’ll need:

Visual guide about how to connect wire conductors to led string lights

Image source: i1.wp.com

- Wire strippers: For cleanly removing insulation without damaging conductors.

- Needle-nose pliers: To twist wires together tightly.

- Heat-shrink tubing or electrical tape: Insulation after connection (heat-shrink is better).

- Heat source (lighter or heat gun): For shrinking tubing.

- Multimeter (optional but recommended): To test continuity and polarity.

- LED string lights: With accessible wire ends (cut or damaged section).

- Replacement wires or extension cord: If adding length or replacing a section.

- Wire connectors (optional): Like Wago or lever nuts for quick, secure connections.

- Safety gloves and glasses: Especially if working with exposed wires near power.

Pro Tip: Always use wires with the same gauge (e.g., 18 AWG) as your LED lights. Mismatched gauges can cause overheating. If extending, ensure the total wattage of all connected strings doesn’t exceed your power source’s capacity—most standard outlets handle 15A, which is about 1,800W (check your lights’ wattage).

Step-by-Step Guide to How to Connect Wire Conductors to LED String Lights Safely

Follow these steps carefully. We’ll use a real-world example: replacing a damaged section of a 24-foot LED string light set. This method works for repairs, extensions, or custom installations.

Step 1: Power Off & Inspect the Damage

Unplug the lights immediately. Even if the damage is obvious (like a chewed cord), never assume it’s safe. Check for exposed copper, melted insulation, or frayed strands. If the damage is near the plug or transformer, consider replacing the whole strand—splicing near the power source increases risk.

Use your multimeter (set to continuity mode) to test if the damaged section has an open circuit. Touch the probes to each conductor (positive and negative). No beep? That confirms a break. This step ensures you’re fixing the right spot.

Safety First: Never work on live wires. Even low-voltage LED transformers can output dangerous voltage (up to 24V AC/DC). If unsure, use a voltage tester before handling conductors.

Step 2: Cut Out the Damaged Section

Use wire cutters to remove the damaged portion. Make clean, straight cuts on both ends of the bad section. Leave at least 1 inch of undamaged wire on each side to work with. If extending lights, cut the original wire where you want the new section to start.

For example, if your string light has a 6-inch chew mark 10 feet from the plug, cut 1 inch before and after the damage. You’ll now have two clean ends: one near the plug, one near the end of the strand.

Pro Tip: Label the wires temporarily with tape. LED strings often use color-coded wires (e.g., red/black or white/green), but not all brands follow standards. Mark the side connected to the plug (“source”) and the side going to the lights (“load”).

Step 3: Strip the Insulation

Use wire strippers to remove ½ inch of insulation from each conductor on both cut ends. Grip the wire firmly and rotate the tool—don’t squeeze too hard, or you’ll nick the copper. Stranded wires can unravel; twist them gently to keep them tight.

Check for oxidation (green or black tarnish). If present, sand the exposed copper lightly with fine-grit sandpaper. Clean conductors ensure better conductivity and a stronger connection.

Why ½ inch? This length gives enough surface area for twisting and securing with heat-shrink or tape. Too short? Weak connection. Too long? Risk of short-circuiting if wires touch.

Step 4: Identify & Match Conductors

LED string lights are polarity-sensitive. Connecting positive to negative will prevent them from working. Here’s how to identify conductors:

- Color coding: Red/black, white/green, or blue/white are common. Red or white is usually positive.

- Wire texture: One wire may have a ridge or stripe (positive).

- Multimeter test: Set to DC voltage. Touch probes to conductors while plugging in the lights briefly (unplug immediately after). The probe on the positive wire will show a positive reading.

Match the same conductors on both sides: positive to positive, negative to negative. If extending, connect the source’s positive to the new wire’s positive, and so on.

Warning: Mismatched polarity won’t damage most LEDs (they’re diode-protected), but they won’t light up. Always double-check before finalizing the connection.

Step 5: Twist Wires Together Securely

Hold the exposed ends of the matching conductors. Use needle-nose pliers to twist them clockwise until tight. For solid wires, create a “pigtail” twist: overlap the wires at a 90-degree angle, then twist one around the other. For stranded wires, twist each end into a point first, then intertwine.

The connection should be snug with no loose strands. Test by gently tugging—it shouldn’t come apart. If it’s loose, untwist and try again. A weak twist is the #1 cause of flickering or intermittent power.

Alternative: Use wire connectors (e.g., Wago 221) for a tool-free, code-compliant connection. Push each conductor into the connector’s port—no twisting needed. Great for beginners or tight spaces.

Step 6: Insulate the Connection

This step is critical for safety and durability. Choose one method:

- Heat-shrink tubing: Slide a 1-inch tube over the twisted wires before connecting. After twisting, center the tube over the joint and heat evenly until it shrinks and seals. Overlap the insulation by ¼ inch on each side.

- Electrical tape: Wrap tightly in overlapping layers, covering ½ inch of insulation on both sides. Stretch the tape slightly as you wrap for a tighter seal. Use high-quality, UL-listed tape.

Heat-shrink is superior—it’s waterproof, abrasion-resistant, and lasts years. Tape can degrade over time, especially outdoors. For outdoor installations, heat-shrink is strongly recommended.

Pro Tip: Use dual-wall adhesive-lined heat-shrink for outdoor or high-moisture areas. It seals out water and adds mechanical strength.

Step 7: Secure the Joint (Optional but Recommended)

To prevent stress on the wires, anchor the connection. Use:

- Cable ties: Loop a zip tie around the joint and a nearby fixture (e.g., a pole or hook).

- Electrical tape: Tape the joint to a rigid surface (e.g., a wooden beam).

Why? Every time you move or wind the lights, the joint bears the strain. Anchoring prevents the wires from pulling apart over time.

Step 8: Test Before Finalizing

Plug in the lights and check:

- Do all bulbs light up? No flickering?

- Is the joint warm or hot? (A warm joint is normal; hot indicates a bad connection.)

- Use a multimeter to test voltage at the far end. It should match the original output (e.g., 12V).

If issues occur, unplug immediately. Check for:

- Short circuits (wires touching)

- Loose twists

- Incorrect polarity

Once everything works, tidy up with cable ties and hide the joint (e.g., under a gutter or behind a curtain).

Pro Tips & Common Mistakes to Avoid

Even small errors can ruin your project. Here’s what the pros know:

- Use the right wire gauge: Most LED strings use 18-22 AWG. Using a thinner wire (e.g., 24 AWG) for extensions causes voltage drop—lights dim or flicker.

- Don’t skip insulation: Exposed copper is a fire hazard. Always cover 100% of the connection.

- Match conductor types: Solid and stranded wires can be connected, but use a connector or solder for a secure bond. Twisting them directly often fails.

- Label your work: If splicing multiple strings, label each end (“String 1,” “Extension A”) to avoid confusion later.

- Test in stages: For long extensions, test after each splice. Catching an error early saves time.

Common Mistake: Overheating heat-shrink with a lighter. Hold the flame 2–3 inches away and move it constantly. Stop when the tubing shrinks—don’t char it.

Real-Life Scenario: Sarah connected her patio lights but noticed one section was dim. She’d used 24 AWG speaker wire for an extension—too thin for the 20-foot run. Replacing it with 18 AWG fixed the issue.

For permanent outdoor installations, consider soldering the connection before insulating. Solder creates a solid, corrosion-resistant joint. But it requires practice—use rosin-core solder and a 30W iron. Never use acid-core solder (it corrodes wires).

FAQs About How to Connect Wire Conductors to LED String Lights Safely

Q1: Can I connect LED lights to regular extension cords?

Yes, but check the cord’s wattage rating. A 16 AWG indoor extension cord handles ~1,375W (15A). Most LED strings use 5–50W, so it’s safe for a few strands. For heavy loads (e.g., 10+ strings), use a 14 AWG outdoor-rated cord.

Q2: What if my LED lights have 3 or 4 wires?

RGB or color-changing LEDs often have 3+ wires. One is common (usually black or white), and others control colors (red, green, blue). Connect the common wire to the negative (ground) and color wires to their matching positives. Use a multimeter or consult the manual—mismatches can damage the controller.

Q3: Is it safe to cut and reconnect LED strips (not string lights)?

Yes, but only at designated cut points (marked with copper pads). Solder new wires to the pads, then insulate. Never cut between pads—it ruins the circuit. For string lights, you can cut anywhere.

Q4: Why do my lights flicker after connecting?

Common causes: loose wire twists, poor insulation (causing shorts), or voltage drop from thin wires. Test each connection with a multimeter and re-tighten twists. For voltage drop, use thicker wires or shorten the run.

Q5: Can I use wire nuts for LED light connections?

Yes, but only for low-voltage (12–24V) LED systems. For 120V AC strings (rare), use UL-listed wire nuts rated for 120V. Always insulate with tape or heat-shrink after.

Q6: How do I waterproof outdoor connections?

Use adhesive-lined heat-shrink tubing and seal the ends with silicone caulk. For extra protection, place the joint in a waterproof junction box or a sealed plastic bag (with drainage holes).

Q7: What’s the maximum number of LED strings I can connect?

Check the manufacturer’s limit (usually 3–5 strings). Exceeding it overloads the transformer, causing flickering or failure. For long runs, use a higher-wattage transformer or a separate power source.

Final Thoughts

Mastering how to connect wire conductors to LED string lights safely empowers you to customize, repair, and extend your lighting—without risking safety. Whether you’re fixing a chewed cord, creating a holiday display, or building a permanent outdoor setup, the key is patience and attention to detail.

Remember: Always power off, match conductors, insulate completely, and test thoroughly. Use heat-shrink for durability, and anchor joints to prevent stress. When in doubt, consult a professional—especially for high-voltage or complex installations.

Now that you know the steps, try a small project first (e.g., replacing a 6-inch section). As you gain confidence, tackle bigger challenges. Your lights will not only look great—they’ll stay safe and functional for years. Ready to shine? Grab your tools and get started today!

“`