Featured image for what does rectified mean for led string lights

Image source: media.domita.it

Rectified LED string lights use a rectifier to convert AC power to DC, ensuring consistent brightness and eliminating flickering for a smoother, more reliable glow. This key feature enhances performance, extends bulb life, and reduces eye strain—making rectified LEDs ideal for indoor and outdoor ambiance.

Key Takeaways

- Rectified LEDs convert AC to DC for consistent brightness.

- No flickering ensures smoother, safer illumination.

- Longer lifespan due to reduced electrical stress.

- Stable current prevents voltage spikes and damage.

- Energy efficient with lower heat and power waste.

- Better performance in cold or humid conditions.

📑 Table of Contents

- Understanding the Basics: What Does Rectified Mean for LED String Lights?

- How Rectification Works in LED String Lights

- Benefits of Rectified LED String Lights

- Rectified vs. Non-Rectified LED String Lights: A Side-by-Side Comparison

- How to Identify Rectified LED String Lights: A Buyer’s Guide

- Advanced Applications: Where Rectified LED String Lights Excel

- Conclusion: Why Rectified LED String Lights Are Worth the Investment

Understanding the Basics: What Does Rectified Mean for LED String Lights?

When shopping for LED string lights, you might come across the term “rectified” and wonder what it actually means for your lighting experience. While LED lights are already known for their energy efficiency, longevity, and versatility, the addition of “rectified” in product descriptions often hints at a more refined, high-performance technology. But what does rectified mean for LED string lights, and why should it matter to you? In short, rectification refers to the process of converting alternating current (AC) to direct current (DC)—a critical step in ensuring that LED lights operate smoothly, flicker-free, and with maximum efficiency.

LEDs are inherently DC-powered devices, meaning they require a steady, unidirectional flow of electricity to function optimally. Most homes and buildings, however, use AC power from the grid, which constantly changes direction. Without rectification, this mismatch would cause LEDs to flicker rapidly, reduce their lifespan, and potentially emit an annoying strobing effect. By integrating rectification into LED string lights—either through built-in circuitry or external adapters—manufacturers ensure a stable, clean DC supply. This not only enhances visual comfort but also improves the overall durability and performance of the lights. In this comprehensive guide, we’ll dive deep into the concept of rectification, explore its impact on LED string lights, and help you make informed decisions when selecting the best products for your needs.

How Rectification Works in LED String Lights

The Science Behind AC and DC Power

To fully grasp the importance of rectification, it’s essential to understand the fundamental difference between alternating current (AC) and direct current (DC). AC power, used in household outlets, periodically reverses direction—typically 50 or 60 times per second (measured in Hertz). This oscillation is ideal for long-distance power transmission but not for sensitive electronics like LEDs. On the other hand, DC power flows in one consistent direction, providing a steady voltage that LEDs are designed to use. Without rectification, connecting an LED directly to AC would result in erratic on/off cycles, leading to flickering, reduced efficiency, and potential damage over time.

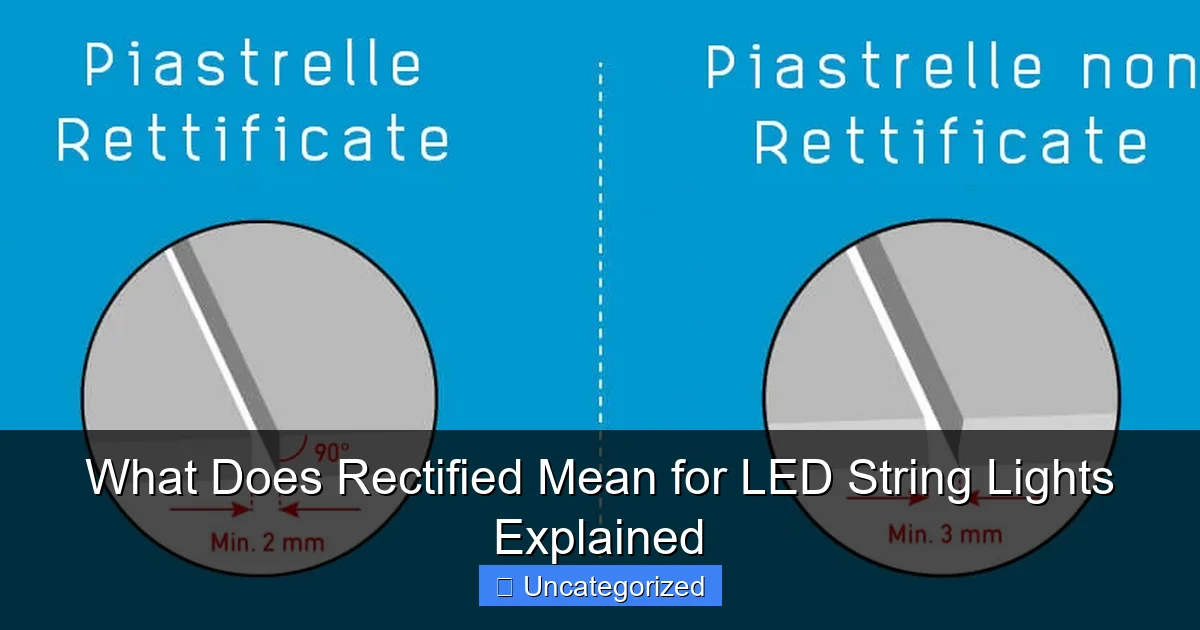

Visual guide about what does rectified mean for led string lights

Image source: i5.walmartimages.com

Rectifiers: The Heart of the Conversion Process

Rectifiers are electronic components that convert AC to DC. In LED string lights, this conversion can happen in one of two ways: through an external power adapter (commonly found in plug-in models) or via integrated rectification circuits within the light string itself (common in low-voltage or battery-operated versions). The most common type of rectifier used is a bridge rectifier, which consists of four diodes arranged to ensure that current flows in only one direction, regardless of the input AC polarity. This process eliminates the negative half of the AC waveform, producing a pulsating DC output that is then smoothed using capacitors to create a more stable voltage.

Types of Rectification: Half-Wave, Full-Wave, and Bridge

- Half-wave rectification: Only uses one half of the AC cycle, making it inefficient and prone to noticeable flickering. Rarely used in modern LED lights.

- Full-wave rectification: Utilizes both halves of the AC cycle by inverting the negative portion, resulting in less ripple and smoother DC output.

- Bridge rectification: A type of full-wave rectifier using four diodes. It’s the most efficient and widely used in commercial LED string lights due to its reliability and compact design.

For example, a high-quality rectified LED string light used for holiday decorations will likely use a bridge rectifier to eliminate flicker and ensure consistent brightness, even when powered from a standard 120V AC outlet.

Benefits of Rectified LED String Lights

Elimination of Flicker and Strobe Effects

One of the most significant advantages of rectified LED string lights is the near-total elimination of flicker. Unrectified or poorly rectified LEDs can exhibit a phenomenon called visible flicker, especially at lower frequencies. This flicker, though not always consciously noticeable, can cause eye strain, headaches, and even trigger migraines in sensitive individuals. Rectified lights, by converting AC to smooth DC, operate at a constant voltage, ensuring a steady light output that’s easier on the eyes—particularly important for indoor use, such as in bedrooms, living rooms, or office spaces.

Enhanced Longevity and Durability

LEDs are already known for their long lifespan—often rated for 25,000 to 50,000 hours. However, this lifespan is heavily dependent on stable operating conditions. Frequent voltage fluctuations and reverse current (from unrectified AC) can degrade LED chips and shorten their life. Rectification ensures that LEDs receive a consistent, forward-biased current, reducing thermal stress and minimizing the risk of premature failure. For instance, a study by the U.S. Department of Energy found that properly rectified LED systems can last up to 30% longer than non-rectified equivalents under the same usage conditions.

Improved Color Consistency and Brightness

When LEDs are powered with fluctuating or reversed current, their color temperature and brightness can vary. This is particularly problematic in multi-color or RGB LED strings, where color accuracy is crucial. Rectified power supplies provide a stable voltage, ensuring that each LED emits the same hue and intensity across the entire string. This is especially beneficial for applications like wedding décor, stage lighting, or architectural installations, where visual uniformity is key.

Energy Efficiency and Reduced Heat Output

Rectified LED systems are more energy-efficient because they minimize power loss during conversion. Modern rectifiers and switching power supplies can achieve conversion efficiencies of 85–95%, meaning only 5–15% of energy is lost as heat. Lower heat output not only improves safety but also reduces the load on cooling systems in enclosed fixtures. For example, a 10-meter rectified LED string light drawing 10 watts will generate significantly less heat than a non-rectified version of the same length, reducing the risk of overheating and fire hazards.

Compatibility with Smart Controls and Dimmers

Many modern LED string lights come with smart features like app control, voice integration (Alexa/Google Assistant), or dimming capabilities. These features rely on stable DC power to function correctly. Rectified systems provide the clean power needed for microcontrollers, sensors, and communication modules to operate reliably. A non-rectified or poorly filtered LED string may experience erratic behavior when dimmed, such as flickering or failure to respond—issues that are virtually eliminated with proper rectification.

Rectified vs. Non-Rectified LED String Lights: A Side-by-Side Comparison

Performance and Visual Quality

The most noticeable difference between rectified and non-rectified LED string lights is in their visual performance. Non-rectified LEDs, especially those using simple half-wave rectification, often exhibit a strobe-like flicker that can be captured on camera (due to rolling shutter effects) or detected by the human eye in peripheral vision. This flicker is more pronounced in lower-cost, mass-produced lights. In contrast, rectified lights—particularly those with full-wave or bridge rectifiers and smoothing capacitors—produce a steady, uniform glow. For example, when used in a time-lapse photo or video shoot, rectified lights will appear consistently bright, while non-rectified ones may show alternating dim and bright segments.

Power Supply and Installation Requirements

Non-rectified LED strings often require external drivers or adapters to function safely, which can add bulk and complexity to installation. Rectified lights, especially those with built-in circuitry, are more plug-and-play. Many rectified models use low-voltage DC (e.g., 12V or 24V), which is safer for outdoor use and reduces the risk of electric shock. This makes them ideal for garden lighting, patio installations, or holiday décor where moisture exposure is a concern.

Cost and Value Considerations

Rectified LED string lights tend to be more expensive upfront due to the added components (diodes, capacitors, PCBs). However, the long-term value is higher. Consider this: a $30 rectified LED string with a 50,000-hour lifespan may cost $0.0006 per hour, while a $15 non-rectified version with a 20,000-hour lifespan costs $0.00075 per hour—and may require earlier replacement. Additionally, the energy savings, reduced maintenance, and superior performance make rectified lights a smarter investment for frequent users.

Use Case Scenarios

- Indoor décor (e.g., bedroom, living room): Rectified lights are ideal due to flicker-free operation and eye comfort.

- Outdoor holiday lighting: Rectified low-voltage strings are safer and more reliable in wet conditions.

- Commercial installations (e.g., restaurants, retail): High-quality rectified lights ensure consistent branding and ambiance.

- Photography and video production: Rectified lights prevent flicker artifacts in footage.

How to Identify Rectified LED String Lights: A Buyer’s Guide

Check the Product Specifications

When shopping for rectified LED string lights, the first step is to review the product details. Look for terms like:

- “AC to DC converter”

- “Full-wave rectified”

- “Low-voltage DC output”

- “Flicker-free”

- “Built-in driver”

Manufacturers of high-quality rectified lights will explicitly state these features. Avoid products that only mention “LED string lights” without details about power conversion.

Inspect the Power Adapter or Plug

Rectified LED strings typically use a “wall wart” power adapter that converts AC to DC. These adapters often have a label indicating output voltage (e.g., 12V DC) and amperage. If the adapter is missing or labeled as “AC output,” the lights are likely non-rectified. For example, a 12V DC adapter with a barrel connector is a strong indicator of rectification.

Test for Flicker (When Possible)

Before purchasing in bulk, test a sample light. Use your smartphone camera to record a slow-motion video of the LEDs in motion (e.g., waving the string). If the lights appear to flicker or show dark bands, they may not be properly rectified. Alternatively, observe the lights in a dark room while moving your eyes quickly—visible flicker indicates poor rectification.

Look for Certifications and Brand Reputation

Trusted brands like GE, Philips, and Feit Electric often use high-quality rectification circuits. Look for certifications such as:

- ETL or UL Listed: Indicates safety and electrical compliance.

- Energy Star: Ensures energy efficiency and performance standards.

- RoHS Compliance: Guarantees the absence of hazardous materials in electronics.

These certifications often correlate with better rectification design and overall build quality.

Consider the Application Environment

For outdoor or damp locations, prioritize rectified, low-voltage (12V or 24V) LED strings with IP65 or higher waterproof ratings. These are typically rectified to ensure safety and reliability. For indoor use, rectified AC/DC adapters are sufficient, but ensure the adapter is UL-certified for indoor use.

Advanced Applications: Where Rectified LED String Lights Excel

Architectural and Landscape Lighting

Rectified LED string lights are increasingly used in architectural lighting designs. Their stable output and color consistency make them ideal for outlining buildings, highlighting facades, or creating ambient pathways. For example, a hotel might use rectified warm-white LED strings around its entrance canopy to ensure a welcoming, flicker-free glow that enhances the guest experience. Landscape designers also use rectified RGB strings for color-changing garden features, where smooth transitions between hues are critical.

Event and Stage Lighting

In professional settings, such as concerts, weddings, or theater productions, lighting must be reliable and visually perfect. Rectified LED strings are preferred because they:

- Integrate seamlessly with DMX or smart lighting controllers.

- Maintain color accuracy during long performances.

- Reduce electromagnetic interference (EMI) that can affect audio equipment.

A wedding planner, for instance, might use rectified fairy lights in a tent to avoid flicker during slow-motion video captures or speeches.

Smart Home Integration

Modern rectified LED strings often include Wi-Fi or Bluetooth modules, allowing control via smartphone apps. Brands like Nanoleaf and Philips Hue use advanced rectification to ensure their smart lights respond instantly to commands without lag or flicker. This integration is only possible with clean, stable DC power—something rectified systems provide.

Industrial and Commercial Use

In factories, warehouses, or retail spaces, rectified LED strings are used for safety lighting, signage, or decorative accents. Their durability and low maintenance make them cost-effective. For example, a retail store might use rectified LED strips under shelves to highlight products, with dimming and scheduling features managed through a central system.

Data Table: Rectified vs. Non-Rectified LED String Light Comparison

| Feature | Rectified LED String Lights | Non-Rectified LED String Lights |

|---|---|---|

| Flicker | Minimal to none (DC output) | Noticeable, especially in videos |

| Lifespan | 25,000–50,000+ hours | 10,000–20,000 hours (shorter due to stress) |

| Power Efficiency | 85–95% conversion efficiency | 70–80% (higher energy loss) |

| Color Consistency | High (stable voltage) | Variable (voltage fluctuations) |

| Smart Features | Compatible with dimmers, apps, voice control | Often incompatible or erratic |

| Typical Use Cases | Indoor, outdoor, commercial, professional | Short-term, decorative, low-budget |

| Price Range (per 10m) | $20–$50 | $10–$25 |

Conclusion: Why Rectified LED String Lights Are Worth the Investment

Understanding what “rectified” means for LED string lights empowers you to make smarter, more informed purchases. Rectification isn’t just a technical detail—it’s a critical factor that affects performance, safety, longevity, and visual quality. Whether you’re decorating your home for the holidays, designing a commercial space, or creating content for photography and video, rectified LED lights offer a superior experience by eliminating flicker, ensuring color accuracy, and maximizing energy efficiency.

While rectified lights may cost more upfront, their long-term benefits far outweigh the initial expense. You’ll enjoy longer-lasting lights, reduced maintenance, and a more professional, polished look. From the science of AC-to-DC conversion to practical buying tips and advanced applications, this guide has shown that rectification is not a luxury—it’s a necessity for anyone who values quality lighting. As LED technology continues to evolve, expect rectified systems to become the standard, not the exception. So the next time you shop for LED string lights, remember: look for rectified, and light up your world with confidence.

Frequently Asked Questions

What does “rectified” mean for LED string lights?

Rectified LED string lights use a rectifier circuit to convert alternating current (AC) to direct current (DC), ensuring smoother, flicker-free illumination. This process enhances performance and longevity compared to non-rectified LEDs.

How do rectified LED string lights differ from regular LED lights?

Rectified LED string lights eliminate flicker by converting AC to DC power, while non-rectified LEDs may pulse slightly due to raw AC current. The rectifier circuit also protects LEDs from voltage spikes, improving durability.

Are rectified LED string lights safer than non-rectified ones?

Yes, rectified LED string lights are generally safer because the rectifier stabilizes voltage, reducing risks of overheating or electrical interference. They also minimize flicker, which can cause eye strain in sensitive individuals.

Do rectified LED string lights use more energy?

No, rectified LED string lights are energy-efficient and don’t consume significantly more power than non-rectified LEDs. The rectifier circuit ensures minimal energy loss while providing consistent brightness.

Can I use rectified LED string lights outdoors?

Absolutely! Many rectified LED string lights are designed for outdoor use, with weather-resistant coatings and stable DC power for reliable performance in all conditions. Always check the product’s IP rating for water resistance.

Why do some LED string lights flicker, and can rectification fix it?

Flickering often occurs due to unstable AC power or low-quality drivers. Rectified LED string lights solve this by converting AC to DC, ensuring steady light output without annoying flickers or strobing effects.