Featured image for what size wire do you need for led string lights

Image source: houseilove.com

Choosing the right wire size for LED string lights is crucial to prevent voltage drop and ensure optimal performance. For most residential setups, 18-gauge wire works best for runs under 50 feet, but longer or higher-wattage installations may require 16- or even 14-gauge for safe, efficient power delivery.

Key Takeaways

- Match wire gauge to load: Use 18-22 AWG for typical LED string lights.

- Longer runs need thicker wires: Upgrade to 16 AWG for runs over 50 feet.

- Check total wattage first: Calculate to avoid under-sizing your wire.

- Low-voltage? Use 18-20 AWG: Ideal for 12V/24V LED systems.

- Indoor vs. outdoor matters: Use weatherproof, stranded wire for outdoor setups.

- Always verify manufacturer specs: Follow their wire size recommendations exactly.

📑 Table of Contents

- Understanding Wire Gauge for LED String Lights: The Basics

- Why Wire Gauge Matters for LED String Lights

- Calculating the Right Wire Size: Step-by-Step

- Wire Types and Materials: What to Look For

- Special Considerations for Different LED Light Setups

- Pro Tips and Troubleshooting Common Issues

- Conclusion: Making the Right Choice for Your LED String Lights

Understanding Wire Gauge for LED String Lights: The Basics

When setting up LED string lights for your patio, garden, or holiday display, one of the most overlooked yet critical components is the wire gauge. Choosing the right wire size ensures optimal performance, safety, and longevity of your lighting system. Too thin a wire, and you risk overheating, voltage drop, and even fire hazards. Too thick, and you’re overspending on materials and making installation unnecessarily cumbersome. But how do you determine the perfect wire size for your LED string lights? The answer lies in understanding wire gauge, power requirements, and the environment in which your lights will operate.

Wire gauge, measured in American Wire Gauge (AWG), refers to the diameter of the wire. The lower the AWG number, the thicker the wire and the more current it can carry safely. For LED string lights, which typically draw less power than incandescent bulbs, the wire size needed is often smaller. However, factors like total length of the run, number of lights, voltage (12V vs. 24V vs. 120V), and environmental conditions (indoor vs. outdoor, weather exposure) all play a role. This guide will break down the science behind wire sizing, provide practical examples, and help you avoid common mistakes that could compromise your lighting setup.

Why Wire Gauge Matters for LED String Lights

The Science Behind Current and Resistance

At the heart of wire sizing is the relationship between current (measured in amps), resistance, and heat. Thinner wires (higher AWG numbers) have higher electrical resistance, which causes them to heat up when current flows through them. For LED string lights, which are low-power but can be strung together in long chains, this resistance can lead to voltage drop—a reduction in voltage along the wire length that causes lights at the end of the run to dim or flicker. For example, a 50-foot run of 22 AWG wire powering 200 LEDs may result in noticeable dimming at the far end due to resistance.

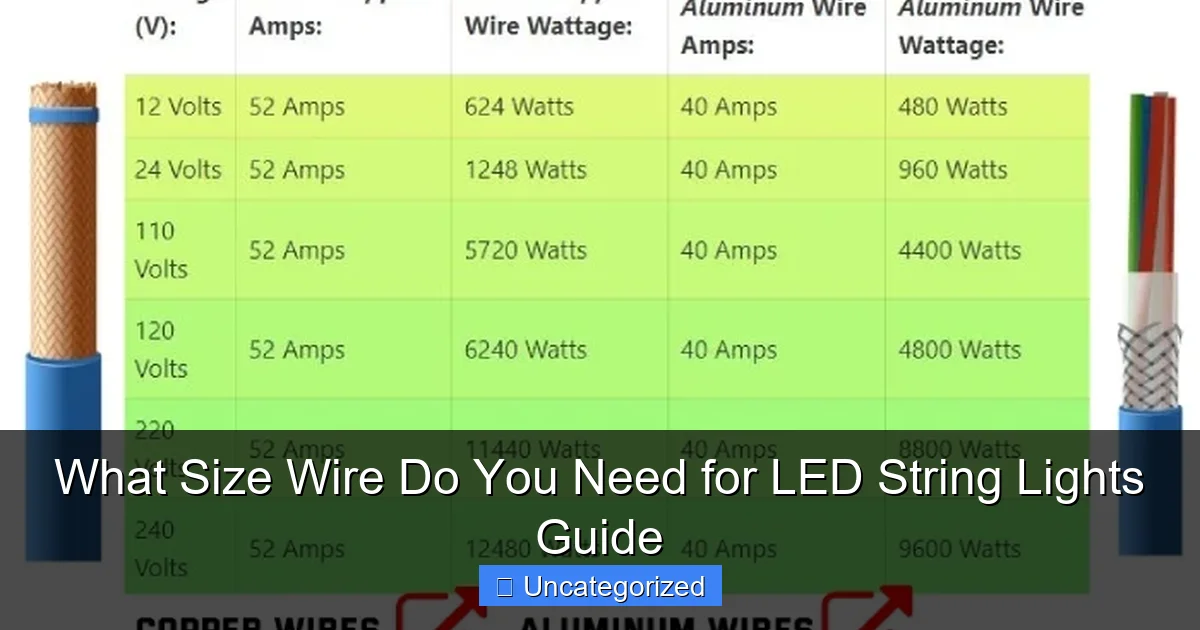

Visual guide about what size wire do you need for led string lights

Image source: learnmetrics.com

The formula to calculate voltage drop is: Voltage Drop = Current (I) × Resistance (R) × Length (L). While you don’t need to calculate this manually for every project, understanding the concept helps you choose a wire gauge that minimizes drop. For instance, doubling the wire length (e.g., from 25 to 50 feet) doubles the voltage drop, while using a thicker wire (e.g., 18 AWG instead of 22 AWG) reduces resistance and drop.

Common Mistakes to Avoid

- Ignoring total wattage: Adding more lights increases current draw. A 100-light LED string at 5W may need a different wire gauge than a 500-light setup at 25W.

- Using undersized extension cords: A 20-foot 18 AWG extension cord might work for a small display but fail when powering a 100-foot light run.

- Overlooking environmental factors: Outdoor wires must be rated for moisture, UV exposure, and temperature changes. A 16 AWG indoor wire may not survive winter weather.

- Mixing wire gauges: Combining thin and thick wires in a single run can create weak points prone to failure.

Calculating the Right Wire Size: Step-by-Step

Step 1: Determine Total Power Requirements

Start by calculating the total power (wattage) of your LED string lights. Check the product label or manual for wattage per bulb or per string. For example:

- A 50-bulb LED string with 0.5W per bulb = 25W total.

- A 200-bulb string at 0.2W per bulb = 40W total.

Next, convert watts to amps using the formula: Amps (I) = Watts (W) ÷ Volts (V). For a 25W, 12V system: 25 ÷ 12 = 2.08A. For a 120V system: 25 ÷ 120 = 0.21A. Lower-voltage systems (12V/24V) draw more current for the same wattage, requiring thicker wires.

Step 2: Measure the Total Wire Run Length

Measure the distance from your power source (outlet, transformer, or battery) to the farthest light in the run. Include any extension cords, splitters, or jumpers. For example:

- 25 feet from outlet to first light + 50 feet between lights = 75-foot total run.

- 10 feet from transformer to first light + 30 feet between lights = 40-foot run.

Longer runs demand thicker wires to minimize voltage drop. A 10-foot run may work with 20 AWG, but a 100-foot run likely needs 16 AWG or thicker.

Step 3: Use a Wire Gauge Chart

Refer to a wire gauge chart to match your current (amps) and length to the appropriate AWG. Below is a simplified guide for common LED string light scenarios:

| Total Length (ft) | Max Current (A) | Recommended AWG (12V/24V) | Recommended AWG (120V) |

|---|---|---|---|

| 10-25 | 1-3 | 20 AWG | 22 AWG |

| 25-50 | 1-3 | 18 AWG | 20 AWG |

| 50-100 | 1-5 | 16 AWG | 18 AWG |

| 100+ | 1-5 | 14 AWG | 16 AWG |

Example: For a 60-foot run of 12V LED string lights drawing 2.5A, use 16 AWG wire. For the same run at 120V (0.2A), 20 AWG suffices.

Step 4: Account for Safety Margins

Always choose a wire gauge one size larger than the chart suggests for safety. For instance, if the chart recommends 18 AWG, use 16 AWG to handle unexpected surges or future expansion. Also, consider using wires rated for 125% of your maximum current to prevent overheating.

Wire Types and Materials: What to Look For

Stranded vs. Solid Core Wires

- Stranded wires: Made of multiple thin strands twisted together. Flexible and ideal for outdoor or frequently moved setups (e.g., holiday lights). Less prone to breakage from vibration. Common for 18 AWG and smaller.

- Solid core wires: Single, rigid wire. Cheaper and easier to terminate (e.g., screw terminals) but less flexible. Prone to breaking if bent repeatedly. Better for permanent installations (e.g., hardwired landscape lighting).

Tip: For DIY LED string light projects, stranded wires are usually the better choice due to their flexibility.

Insulation and Jacket Materials

The wire’s outer insulation protects against environmental damage. Key materials include:

- PVC (Polyvinyl Chloride): Affordable, flexible, and water-resistant. Common for indoor/outdoor extension cords. Avoid in extreme temperatures.

- Rubber (EPDM): Durable, heat-resistant, and ideal for outdoor use. Found in heavy-duty extension cords (e.g., 12 AWG).

- Silicone: High heat tolerance (-60°C to 200°C) and UV-resistant. Best for high-temperature environments (e.g., near grills or in direct sunlight).

- PTFE (Teflon): Chemical-resistant and non-flammable. Used in industrial or marine applications.

For most LED string lights, PVC or rubber insulation is sufficient. For harsh outdoor conditions (e.g., snow, saltwater), opt for rubber or silicone.

Voltage and Current Ratings

Check the wire’s voltage rating (e.g., 300V, 600V) and temperature rating (e.g., 60°C, 90°C). For 120V household systems, a 300V-rated wire is standard. For 12V/24V systems, lower ratings (150V) are acceptable. Avoid wires with temperature ratings below your environment’s extremes (e.g., -20°C for winter installations).

Special Considerations for Different LED Light Setups

Low-Voltage vs. Line-Voltage Systems

Low-voltage (12V/24V) LED string lights are common for gardens, patios, and accent lighting. They draw more current than line-voltage lights for the same wattage, requiring thicker wires. For example:

- A 30W, 12V system draws 2.5A, needing 16 AWG for a 50-foot run.

- The same 30W at 120V draws only 0.25A, allowing 20 AWG for the same run.

Line-voltage (120V/240V) LED string lights are used for holiday displays, commercial lighting, and large-scale installations. They draw less current but require insulation rated for high voltage (e.g., 300V).

Indoor vs. Outdoor Installations

- Indoor: PVC-insulated stranded wires (18-22 AWG) are usually sufficient. Ensure the wire is rated for dry locations (marked “D” on the jacket).

- Outdoor: Use wires with rubber or silicone jackets, UV resistance, and wet location ratings (marked “W”). For buried wires, use direct-burial-rated cables (e.g., UF-B) with 12-14 AWG.

Example: A 200-light outdoor Christmas display (120V, 20W) with a 40-foot run can use 18 AWG rubber-jacketed wire. For a 12V garden setup (30W, 60-foot run), use 16 AWG silicone-insulated wire.

Commercial and Large-Scale Installations

For large projects (e.g., wedding venues, festivals), consider:

- Power distribution boxes: Split the load into multiple circuits to reduce wire length and current per run.

- 12 AWG or 10 AWG wires: For runs exceeding 100 feet or high-wattage setups (100+W).

- Professional-grade connectors: Use waterproof, twist-lock connectors (e.g., L5-20) to prevent disconnections.

Pro Tips and Troubleshooting Common Issues

Minimizing Voltage Drop in Long Runs

- Use higher voltage: 24V systems reduce current by 50% compared to 12V, minimizing drop.

- Inject power at multiple points: Add secondary power sources along the run (e.g., every 50 feet).

- Choose thicker wires: Upgrade from 18 AWG to 14 AWG for runs over 75 feet.

- Use LED drivers with compensation: Some drivers automatically adjust voltage to counteract drop.

Handling Weather and Environmental Stress

- UV-resistant wires: Prevent degradation from sunlight. Look for “UV” on the jacket.

- Temperature ratings: Ensure wires can handle your climate’s extremes (e.g., -40°C for Arctic winters).

- Moisture protection: Use waterproof connectors and seal wire entry points with silicone.

When to Upgrade Your Wires

Signs your current wires are undersized:

- Lights dimming at the end of the run.

- Wires feeling warm or hot to the touch.

- Flickering or inconsistent brightness.

- Frequent blown fuses or tripped breakers.

If you notice these issues, upgrade to a thicker wire gauge or shorten the run by adding power injection points.

Cost vs. Performance: Balancing Budget and Quality

Thicker wires cost more per foot, but the investment pays off in reliability and safety. A 100-foot spool of 16 AWG wire may cost $50, while 18 AWG costs $30. However, 16 AWG reduces voltage drop by 30% in long runs, preventing costly replacements or fire risks. For temporary setups (e.g., holiday lights), thinner wires may suffice. For permanent installations, prioritize quality.

Conclusion: Making the Right Choice for Your LED String Lights

Choosing the right wire size for your LED string lights isn’t just about following a chart—it’s about understanding your system’s unique needs. Whether you’re illuminating a cozy patio with 12V fairy lights or powering a 100-foot holiday display, the right wire gauge ensures safety, efficiency, and stunning results. Remember to calculate your total wattage, measure the run length, and account for environmental factors like weather and voltage. Use stranded wires for flexibility, opt for rubber or silicone insulation outdoors, and don’t skimp on safety margins.

By following this guide, you’ll avoid common pitfalls like voltage drop, overheating, and premature failure. And when in doubt, go one size larger—it’s always better to have a wire that’s slightly overkill than one that’s dangerously undersized. With the right wire, your LED string lights will shine bright, last longer, and create the perfect ambiance for any occasion. Happy lighting!

Frequently Asked Questions

What size wire do you need for LED string lights?

For most LED string lights, a 20- to 22-gauge wire is sufficient due to their low power consumption. Thicker wires (like 18-gauge) are only needed for longer runs or high-wattage setups to prevent voltage drop. Always check the manufacturer’s specifications for exact requirements.

Can I use thin wire for LED string lights?

Yes, thin wires (20-22 gauge) work well for standard LED string lights since they draw minimal current. However, for installations exceeding 50 feet or connecting multiple strands, opt for thicker wire to maintain brightness and efficiency.

Does wire size affect LED string light performance?

Wire size impacts voltage drop—undersized wires can cause dimming or flickering in long runs. For optimal performance, match the wire gauge to the total wattage and distance, especially for outdoor or commercial LED string lights.

What gauge wire is best for outdoor LED string lights?

For outdoor LED string lights, use 18- to 20-gauge wire to handle weather conditions and longer distances. Thicker wires reduce resistance and ensure consistent brightness, especially if the lights are exposed to moisture or temperature changes.

Do I need special wire for battery-powered LED string lights?

Battery-powered LED string lights typically use 22-gauge wire, as they operate at low voltage and short distances. Special wire isn’t necessary unless you’re modifying the lights or extending the cord beyond the original design.

How do I choose the right wire size for LED string lights?

Calculate the total wattage and distance of your setup: 22-gauge for short, low-wattage runs, and 18-20 gauge for longer or high-wattage installations. Refer to the LED string lights’ manual for precise wire size recommendations.