Featured image for can a led light string be shortened

Image source: ledlightinginfo.com

Yes, an LED light string can be safely shortened if done correctly, allowing you to customize length without damaging the circuit. Always cut between designated cut points—usually marked with a scissor icon—and ensure wires are properly insulated to maintain functionality and safety.

Key Takeaways

- Yes, LED strings can be shortened if they have cut marks or modular connectors.

- Always unplug before cutting to avoid electrical hazards or damage.

- Use sharp wire cutters for clean, precise cuts without fraying wires.

- Seal cut ends properly with heat shrink tubing or waterproof tape.

- Check voltage after shortening to ensure remaining lights function correctly.

- Non-cuttable LED strips require professional tools or replacement instead.

- Follow manufacturer guidelines to avoid voiding warranties or causing malfunctions.

📑 Table of Contents

- Understanding LED Light Strings and Their Construction

- Can You Actually Shorten a LED Light String?

- Step-by-Step Guide to Shortening a LED Light String

- Common Mistakes and How to Avoid Them

- Advanced Techniques and Customization

- Data Table: LED String Shortening Guidelines

- Conclusion: Shortening LED Light Strings Safely and Effectively

Understanding LED Light Strings and Their Construction

How LED Light Strings Are Built

Before diving into whether a LED light string can be shortened, it’s essential to understand how these decorative lighting products are constructed. Most modern LED light strings consist of a series of tiny light-emitting diodes (LEDs) connected in either a series, parallel, or series-parallel circuit configuration. The design depends on the manufacturer and the intended use—indoor, outdoor, holiday displays, or permanent installations.

In a series circuit, each LED is connected end-to-end, meaning the current flows through one LED after another. If one LED fails, the entire string typically goes dark unless it includes a shunt resistor or bypass diode, which allows current to continue flowing even if an individual LED burns out. In contrast, parallel circuits connect each LED directly to the power source, so if one fails, the others remain lit. Series-parallel strings combine both methods, offering a balance between brightness, reliability, and energy efficiency.

Additionally, LED strings are often powered by low-voltage direct current (DC), especially those using battery packs or plug-in transformers. The voltage (typically 3V, 12V, or 24V) and current (measured in milliamps) are carefully balanced to ensure optimal performance. The wires used are usually thin gauge (20–26 AWG), and the insulation is designed to be flexible and weather-resistant, particularly for outdoor models.

Components That Affect Shortening

Several components influence whether a LED light string can be safely shortened:

- Cut Points: Some LED strings have designated cut points—small markings or notches—indicating where the wire can be safely cut without damaging the circuit.

- Controller and Power Source: Many strings include a controller box that manages lighting modes (steady, blinking, color changes). This box must remain connected to the shortened section.

- Waterproofing and Seals: Outdoor-rated strings often have sealed connections or silicone coatings. Cutting these can compromise weather resistance.

- Wire Gauge and Length: Shorter wires have less resistance, but cutting too much can alter voltage drop across the remaining LEDs, potentially causing uneven brightness.

- End Caps and Terminals: Some strings have end caps or plugs at the end of the circuit. Removing these without proper sealing can lead to short circuits or exposed wires.

Understanding these components is crucial before attempting any modifications. A misstep can result in a non-functional string, electrical hazards, or voiding of the warranty.

Can You Actually Shorten a LED Light String?

General Feasibility and Manufacturer Design

Yes, a LED light string can be shortened—but with important caveats. The feasibility depends on the string’s design and the type of circuit it uses. For example, strings with cut points (also called “cuttable segments”) are explicitly designed for customization. These are common in commercial-grade LED strips (like 12V or 24V addressable RGB strips) and some holiday light sets.

Visual guide about can a led light string be shortened

Image source: ledlightinginfo.com

However, not all LED strings are cuttable. Standard holiday light strings (e.g., 50- or 100-LED sets) are often not designed for shortening. Cutting them without proper knowledge can:

- Break the circuit, rendering the entire string inoperable.

- Cause voltage imbalances, leading to dim or overly bright LEDs.

- Expose bare wires, creating fire or shock hazards.

Manufacturers like Philips, GE, and Twinkly often include instructions or markings on packaging or the wire itself indicating whether the string is cuttable. Always check for phrases like “cuttable every 3 LEDs” or symbols (e.g., scissors icon) at regular intervals.

Types of LED Strings That Can Be Shortened

Here are the most common types of LED strings that are safely cuttable:

- LED Strip Lights (Flexible Strips): These are the most user-friendly. They’re typically sold in 5-meter reels with cut points every 2.5–5 cm (1–2 inches), depending on the density (e.g., 30, 60, or 120 LEDs per meter). They’re used for under-cabinet lighting, cove lighting, and decorative accents.

- Cuttable Holiday Lights: Some modern holiday strings (e.g., Twinkly, Govee) use addressable LEDs with built-in cut points. These allow you to shorten the string while maintaining full functionality and app control.

- Low-Voltage Landscape Lights: Often designed for garden paths or trees, these use 12V transformers and have modular connectors that can be detached and reattached.

- Commercial Grade Strings: Used in permanent installations (e.g., storefronts, theaters), these are built for customization and often come with soldering pads or quick-connect terminals.

Conversely, avoid shortening:

- Non-cuttable holiday lights (most incandescent or older LED sets).

- Strings with no visible cut points or instructions.

- Strings with integrated battery packs or controllers that can’t be relocated.

Step-by-Step Guide to Shortening a LED Light String

Tools and Materials You’ll Need

Before starting, gather these tools and materials:

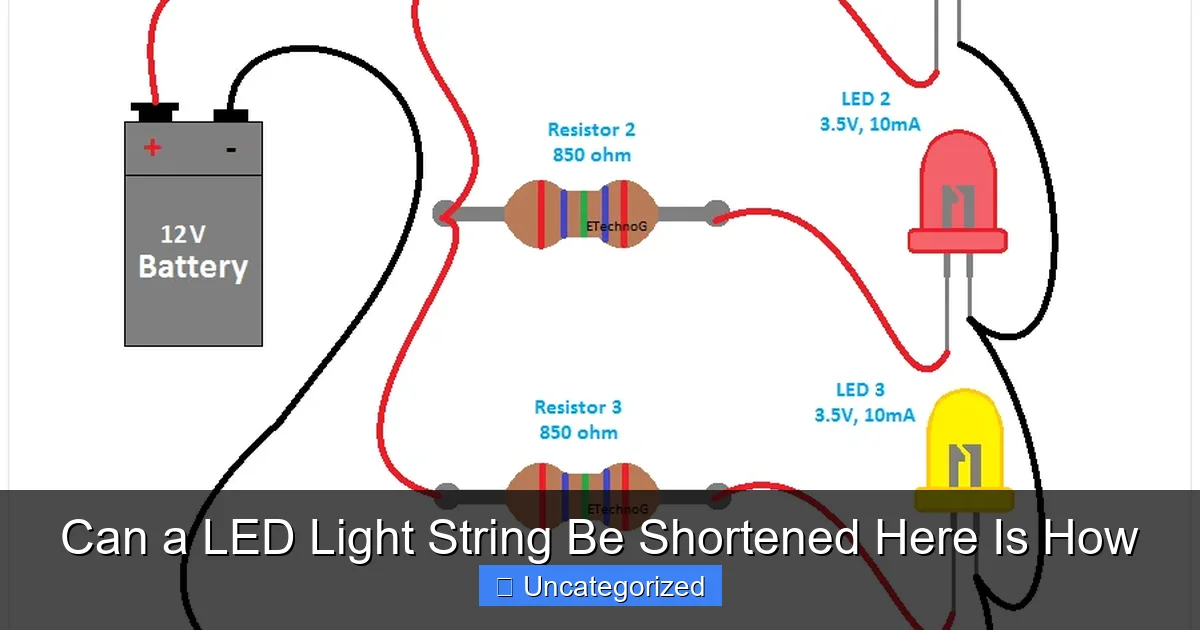

Visual guide about can a led light string be shortened

Image source: i0.wp.com

- Wire cutters or sharp scissors

- Wire strippers (if re-terminating wires)

- Electrical tape or heat-shrink tubing

- Soldering iron and solder (for permanent connections)

- Multimeter (to test voltage and continuity)

- Insulated connectors (e.g., butt splices, Wago connectors)

- Marker or tape (to mark cut points)

- Heat gun (if using heat-shrink tubing)

For waterproof strings, you may also need silicone sealant or waterproof connectors.

Step 1: Identify Cut Points and Test the String

Begin by inspecting the string for cut points. Look for:

- Scissors icons or notches on the wire.

- Markings like “Cut Here” or “÷” symbols.

- Small rectangles on LED strips (indicating solder pads).

Test the string first to ensure it works. Plug it in and verify all LEDs light up. Use a multimeter to check voltage at the power source and along the string. For 12V strips, the voltage at the end should be close to 12V. A significant drop (e.g., 8V at the end) indicates excessive length, which shortening can resolve.

Step 2: Measure and Mark the Desired Length

Determine where to cut based on your space. For example:

- For a 10-foot window trim, measure and mark at 7 feet.

- For a tree, count the number of LEDs needed and mark at the last usable cut point.

Always cut after a complete segment (e.g., cut after the 30th LED, not between the 29th and 30th). Never cut between individual LEDs unless the manufacturer specifies it.

Step 3: Cut and Seal the Wire

Using wire cutters, snip the wire at the marked cut point. For LED strips, cut along the marked line between solder pads. For traditional strings, cut the positive and negative wires simultaneously.

After cutting:

- For non-waterproof strings: Wrap the cut end with electrical tape. Ensure no bare wire is exposed.

- For waterproof strings: Use heat-shrink tubing or silicone sealant. Slide the tubing over the cut end and heat it until it contracts. Apply silicone around the seal for added protection.

Tip: If you plan to reuse the cut-off section, solder wires to the cut end and add a connector (e.g., JST plug).

Step 4: Reconnect the Power Source (If Needed)

If you’re shortening a string with a plug-in transformer:

- Keep the plug and controller box attached to the shortened section.

- For LED strips, solder wires to the cut end and connect them to the power supply (observe polarity: “+” to “+”, “-” to “-“).

- Use insulated connectors or solder and heat-shrink tubing for a secure connection.

Never leave exposed wires unconnected. This can cause short circuits or electrical shocks.

Common Mistakes and How to Avoid Them

Cutting at the Wrong Location

One of the most frequent errors is cutting between LEDs instead of at designated cut points. This severs the circuit, leaving the remaining LEDs unpowered. To avoid this:

- Always cut at marked segments.

- For LED strips, cut only along the copper pads between LEDs.

- If unsure, consult the manufacturer’s manual or website.

Example: A user shortened a 60-LED/meter strip by cutting between the 50th and 51st LED. The first 50 LEDs lit up, but the rest remained dark because the circuit was broken. They had to solder a jumper wire to restore the connection.

Ignoring Polarity and Voltage

LEDs are polarized—they only work when current flows in the correct direction. Reversing polarity (connecting “+” to “-” and vice versa) can damage LEDs or render them inoperative. Always:

- Check polarity markings on the strip or controller.

- Use a multimeter to verify voltage and direction.

- Label wires during disassembly (e.g., red for “+”, black for “-“).

Voltage is another critical factor. Cutting a string too short can cause the remaining LEDs to draw excessive current, leading to overheating. For example, a 12V string shortened from 5 meters to 1 meter may experience a voltage surge, burning out the LEDs. To prevent this, use a voltage regulator or choose a string with a built-in current limiter.

Failing to Waterproof or Insulate

Cutting a string creates exposed wires, which are hazardous, especially outdoors. Common mistakes include:

- Using electrical tape that degrades over time (replace with heat-shrink tubing).

- Neglecting to seal connections in humid or rainy environments.

- Forgetting to test the seal by spraying water (for outdoor use).

Tip: For outdoor installations, use IP67-rated connectors and seal all joints with silicone.

Overloading the Circuit

When shortening multiple strings and connecting them in parallel, avoid overloading the power supply. Each LED draws a small current (e.g., 20mA per LED), and exceeding the transformer’s capacity can cause overheating or failure. Use this formula to calculate total current draw:

Total Current (Amps) = Number of LEDs × Current per LED (Amps)

For example, 100 LEDs at 0.02A each = 2A total. Ensure your power supply can handle at least 1.2× this value (2.4A in this case).

Advanced Techniques and Customization

Adding Connectors and Splicing

For permanent installations, consider adding connectors to make the shortened string reusable. Options include:

- Solder-on Connectors: JST, Molex, or barrel connectors soldered to the cut end.

- Quick-Connect Terminals: Push-in connectors (e.g., Wago 221) for tool-free splicing.

- Terminal Blocks: For high-current applications (e.g., 12V landscape lights).

Example: A homeowner shortened a 12V LED strip for a bookshelf. They soldered a JST connector to the cut end and attached a matching plug to the power supply, allowing easy removal for cleaning.

Using Controllers and Smart Features

Modern LED strings often include smart features (app control, voice activation, color changing). When shortening these:

- Keep the controller box attached to the shortened section.

- For addressable LEDs (e.g., WS2812B), reprogram the controller to recognize the new length.

- Use software like WLED or Philips Hue to adjust the LED count in the app.

Tip: Some controllers (e.g., Arduino-based) allow you to set the exact number of LEDs via code, preventing “ghost” LEDs from appearing in animations.

Creating Custom Shapes and Designs

Shortening isn’t just about length—it enables creative designs:

- Geometric Patterns: Cut strips into triangles, hexagons, or stars for wall art.

- Tree Wrapping: Shorten strings to wrap around branches without excess.

- Under-Cabinet Lighting: Customize lengths to fit cabinet edges precisely.

For complex shapes, use a breadboard or PCB to connect segments at angles, ensuring consistent voltage.

Data Table: LED String Shortening Guidelines

| LED String Type | Cuttable? | Cut Point Interval | Recommended Tools | Waterproofing Method | Notes |

|---|---|---|---|---|---|

| LED Strip (30 LEDs/m) | Yes | Every 10 cm (3 LEDs) | Scissors, solder iron | Heat-shrink tubing | Cut between solder pads |

| LED Strip (60 LEDs/m) | Yes | Every 5 cm (3 LEDs) | Scissors, solder iron | Heat-shrink tubing | High density; avoid overheating |

| Holiday String (Cuttable) | Yes | Marked intervals (e.g., every 5 LEDs) | Wire cutters | Silicone sealant | Check for “cuttable” label |

| Non-Cuttable Holiday String | No | N/A | N/A | N/A | Do not cut; use multiple strings |

| 12V Landscape String | Yes | Modular connectors | Wire strippers, connectors | IP67 connectors | Use 12V transformer |

| Addressable RGB String | Yes (with reprogramming) | Cut points every 1–3 LEDs | Scissors, multimeter | Heat-shrink tubing | Update controller settings |

Conclusion: Shortening LED Light Strings Safely and Effectively

Shortening a LED light string is not only possible but often necessary for custom installations, space optimization, and creative projects. However, success hinges on understanding the string’s design, following manufacturer guidelines, and using the right tools and techniques. Whether you’re trimming a holiday light set for a smaller tree or customizing LED strips for a kitchen backsplash, the process requires precision and caution.

Key takeaways include:

- Check for cut points before modifying any string.

- Preserve the circuit by cutting at designated segments and maintaining polarity.

- Insulate and waterproof all cut ends to ensure safety and longevity.

- Use appropriate tools and test the string after modification.

- Leverage smart features for advanced customization.

With these principles in mind, you can transform off-the-shelf LED strings into personalized, functional lighting solutions. Always prioritize safety—when in doubt, consult a professional or opt for pre-cut strings designed for your specific needs. By mastering the art of shortening LED light strings, you unlock endless possibilities for lighting design, both indoors and out.

Frequently Asked Questions

Can a LED light string be shortened without damaging it?

Yes, most LED light strings can be safely shortened if they have designated cut points, usually marked by a pair of scissors icon. Always check the manufacturer’s guidelines to avoid damaging the circuit or creating a safety hazard.

Where should I cut a shortened LED light string?

Look for cut points along the wire—these are typically marked every few inches or at the end of a light segment. Cutting outside these points may cause the remaining lights to stop working.

Is it safe to shorten a LED string light on my own?

It’s generally safe if you follow the manufacturer’s instructions and cut only at designated points. Improper cutting or soldering can damage the lights or create electrical risks.

Can a shortened LED light string still be connected to a power source?

Yes, as long as you leave the plug or controller intact and only cut beyond the last light you want to keep. Ensure the exposed wires are properly sealed if the cut end won’t be connected.

What tools do I need to shorten a LED light string?

You typically only need a pair of sharp scissors or wire cutters. Some advanced modifications may require wire strippers or soldering tools, but most LED strings are designed for simple, tool-free shortening.

Can a shortened LED string light be extended again later?

Once cut, a LED light string cannot be reconnected without electrical work. You’d need to splice and solder the wires or use connector kits, which may void warranties and affect performance.