Featured image for are led string lights parallel or series

Image source: i.ytimg.com

Most LED string lights use a parallel circuit design, allowing individual bulbs to stay lit even if one fails, ensuring reliability and longer lifespan. This setup also maintains consistent brightness across all LEDs, unlike series circuits where a single failure can disrupt the entire strand—making parallel wiring the preferred choice for modern, durable lighting.

Key Takeaways

- Most LED string lights use parallel circuits for independent bulb operation and consistent brightness.

- Series circuits are rare due to voltage drop and single-point failure risks.

- Check for dimming bulbs to identify series connections in older models.

- Parallel wiring simplifies troubleshooting—one faulty bulb won’t disable the entire strand.

- Hybrid designs exist—some combine parallel and series for efficiency and safety.

- Always verify with a multimeter if unsure about your lights’ wiring configuration.

📑 Table of Contents

- Understanding LED String Light Circuits: The Basics

- What Are Parallel and Series Circuits?

- Are LED String Lights Wired in Parallel or Series?

- Pros and Cons of Each Wiring Configuration

- How Wiring Affects Performance and Maintenance

- Data Table: Comparison of LED String Light Wiring Types

- Conclusion: Making the Right Choice for Your Needs

Understanding LED String Light Circuits: The Basics

LED string lights have become a staple in modern lighting design, gracing everything from holiday decorations to cozy bedroom setups. Their energy efficiency, durability, and vibrant colors make them a popular choice for both indoor and outdoor use. However, one of the most frequently asked questions about these lights is: Are LED string lights parallel or series? The answer isn’t always straightforward and depends on the specific design of the light string. Understanding the electrical configuration—whether the LEDs are wired in parallel or series—is crucial for troubleshooting, extending the life of your lights, and even creating custom installations.

Whether you’re a DIY enthusiast, a homeowner looking to upgrade your lighting, or simply curious about how these tiny bulbs work, this guide will demystify the wiring behind LED string lights. We’ll explore the differences between parallel and series circuits, how they affect performance, and why manufacturers choose one over the other. By the end of this article, you’ll be equipped with the knowledge to make informed decisions about your LED string lights, from purchasing to maintenance.

What Are Parallel and Series Circuits?

Defining Series Circuits

In a series circuit, components (in this case, LEDs) are connected end-to-end in a single path. This means that the same current flows through each LED in the chain. The total voltage across the circuit is the sum of the voltage drops across each individual LED. For example, if you have 10 LEDs each requiring 3 volts, the total voltage needed to power the string would be 30 volts (assuming they’re all in series).

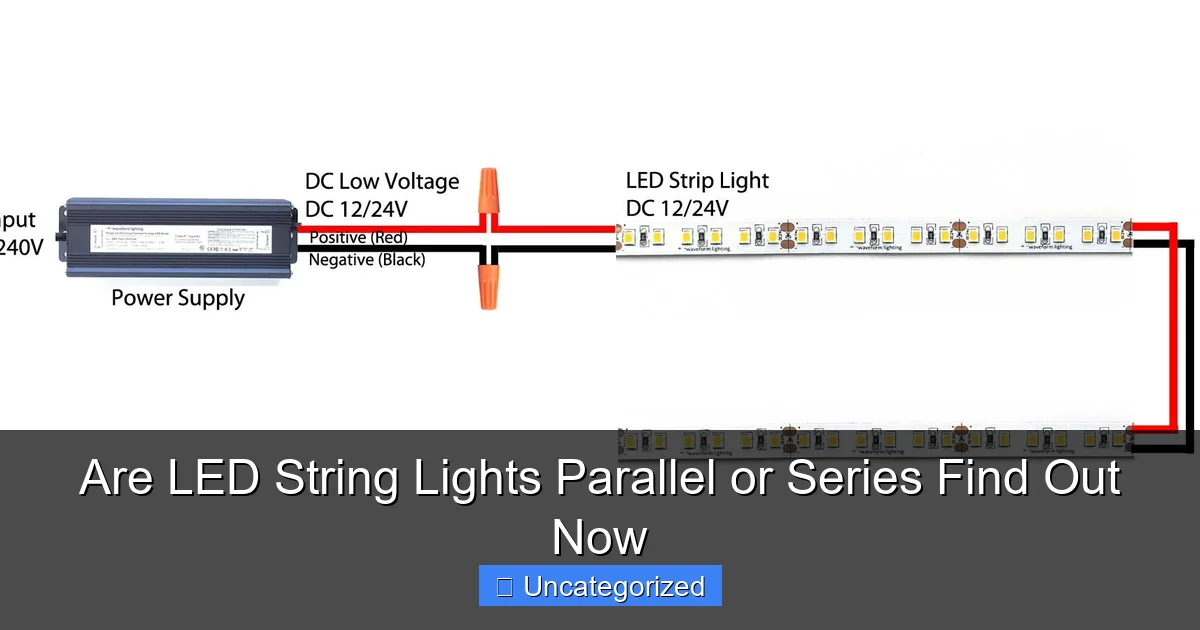

Visual guide about are led string lights parallel or series

Image source: waveformlighting.com

A key characteristic of series circuits is that if one LED fails (typically by burning out or becoming disconnected), the entire circuit is interrupted. This results in the whole string going dark—a common frustration with older holiday lights. This phenomenon is known as a single point of failure.

Defining Parallel Circuits

In a parallel circuit, each LED is connected across the same two points, forming multiple independent paths for current. This means that the voltage across each LED is the same, but the total current is the sum of the currents through each branch.

The primary advantage of parallel wiring is redundancy. If one LED fails, the others continue to operate because they each have their own dedicated path. This makes parallel circuits more reliable and user-friendly, especially in decorative lighting where a single dead bulb shouldn’t ruin the entire display.

Hybrid and Constant Current Designs

Modern LED string lights often use hybrid circuits, which combine elements of both series and parallel wiring. For instance, a string might have groups of LEDs wired in series (called a “string segment”) and multiple such segments connected in parallel. This design allows manufacturers to balance voltage requirements, improve reliability, and reduce the risk of total failure.

Another innovation is the use of constant current drivers or resistor networks to regulate current flow, ensuring that each LED receives the correct amount of power regardless of minor variations in the circuit. This is particularly important because LEDs are sensitive to overcurrent, which can drastically shorten their lifespan.

Are LED String Lights Wired in Parallel or Series?

Manufacturer Design Choices

The wiring configuration of LED string lights is primarily determined by the manufacturer’s design goals. These goals include cost efficiency, energy consumption, brightness consistency, and reliability. Most modern LED string lights use a combination of series and parallel circuits rather than pure series or parallel wiring.

Visual guide about are led string lights parallel or series

Image source: cdn1.homewaresinsider.com

For example, a typical 100-LED string might be divided into 10 segments of 10 LEDs each, with each segment wired in series and the segments connected in parallel. This design reduces the overall voltage requirement (since each segment only needs 30 volts for 10 LEDs at 3V each) while ensuring that if one LED fails, only its segment goes out—not the entire string.

Some high-end or specialty LED lights (e.g., addressable RGB strings like those used in smart lighting systems) use individual parallel connections with microcontrollers, allowing each LED to be controlled independently. These are often used in advanced installations like programmable holiday displays or architectural lighting.

How to Identify the Circuit Type

You can often determine whether an LED string uses series, parallel, or hybrid wiring by conducting a simple test:

- Single LED Failure Test: Carefully remove or short-circuit one LED (if it’s accessible). If only that LED turns off and the rest remain lit, it’s likely a parallel or hybrid circuit. If the entire string goes out, it’s probably a series circuit.

- Check the Packaging: Some manufacturers specify the wiring type on the packaging or in the user manual. Look for terms like “fail-safe,” “independent operation,” or “segmented design.”

- Inspect the Wiring (if possible): Open the light string’s plug or control box (only if it’s safe and you’re experienced with electronics). Parallel circuits often have multiple wires branching off, while series circuits have a single continuous wire.

- Use a Multimeter: Measure voltage and current at different points in the circuit. In a series circuit, the voltage adds up; in parallel, the voltage is constant across each branch.

Tip: Always unplug the lights before performing any tests. Safety first!

Common Industry Practices

Most mass-market LED string lights (e.g., those sold by retailers like Amazon, Home Depot, or Target) use hybrid series-parallel designs for the following reasons:

- Lower Voltage Requirements: Series segments reduce the need for high-voltage power supplies, making the lights safer and more compatible with standard 120V/230V outlets (via adapters).

- Improved Reliability: Parallel connections between segments ensure that one failed LED doesn’t ruin the entire display.

- Cost-Effective Manufacturing: Hybrid circuits are easier and cheaper to produce at scale than fully parallel designs, which require more complex wiring.

Pros and Cons of Each Wiring Configuration

Advantages of Series Wiring

While pure series wiring is rare in modern LED strings, it still has some benefits:

- Simpler Design: Fewer wires and connections reduce manufacturing complexity.

- Consistent Brightness: Since the same current flows through each LED, brightness is uniform (assuming identical LEDs).

- Lower Current Draw: High voltage and low current reduce energy losses in the wiring, improving efficiency.

Example: Some battery-powered LED strings (e.g., fairy lights) use series wiring because they operate at low voltages (3V or 6V) and don’t need high reliability.

Disadvantages of Series Wiring

- Single Point of Failure: One dead LED can disable the entire string.

- Voltage Scaling: Long strings require high input voltage, which may necessitate bulky power supplies or step-up converters.

- Difficult Troubleshooting: Locating a single failed LED in a long series chain is time-consuming.

Tip: If you have a series-wired string and one LED fails, you can sometimes “bypass” it with a small jumper wire (e.g., a paperclip) to restore the circuit. However, this may reduce brightness in the remaining LEDs.

Advantages of Parallel Wiring

- High Reliability: Individual LED failures don’t affect the rest of the string.

- Easier Maintenance: Replacing a dead LED is simpler because you can isolate it.

- Scalability: You can add more LEDs without drastically increasing voltage requirements.

Example: Smart LED strips (e.g., Philips Hue) use parallel wiring with individual control chips, enabling dynamic lighting effects.

Disadvantages of Parallel Wiring

- Higher Current Draw: More LEDs mean higher total current, requiring thicker wires and robust power supplies.

- Brightness Inconsistency: If one LED draws slightly more current, it can dim nearby LEDs (unless regulated by resistors or drivers).

- Increased Manufacturing Cost: More complex wiring and components raise production costs.

Tip: For parallel-wired strings, use a power supply with a slightly higher current rating than the total draw to avoid overloading.

Hybrid Wiring: The Best of Both Worlds

Hybrid designs offer a balanced approach:

- Reliability: Parallel segments prevent total failure.

- Efficiency: Series segments within each group reduce voltage needs.

- Flexibility: Manufacturers can customize segment length and number for different applications.

Example: A 50-foot commercial LED rope light might have 20 segments of 25 LEDs each, wired in series-parallel for optimal performance.

How Wiring Affects Performance and Maintenance

Brightness and Color Consistency

The wiring configuration directly impacts how evenly the LEDs light up. In series circuits, brightness is consistent because the same current flows through each LED. However, if one LED degrades over time (e.g., due to heat or age), it can affect the entire chain.

In parallel circuits, each LED has its own current path, so brightness depends on individual components. Poorly matched LEDs or faulty resistors can cause noticeable differences in brightness or color temperature. Hybrid circuits mitigate this by grouping LEDs in series, ensuring uniformity within each segment.

Failure Rates and Lifespan

LEDs are inherently long-lasting (typically 25,000–50,000 hours), but wiring design influences their real-world lifespan:

- Series Wiring: High failure rate per string due to single-point failures. However, if one LED fails and isn’t replaced, the remaining LEDs may overheat and fail prematurely.

- Parallel Wiring: Lower failure rate per string. Failed LEDs don’t stress the others, but the power supply may degrade faster due to higher total current.

- Hybrid Wiring: Balanced failure rate. Segment failures are isolated, but the power supply must handle both voltage and current demands.

Tip: To extend lifespan, avoid exposing LED strings to moisture, extreme temperatures, or physical stress (e.g., twisting or bending).

Troubleshooting Common Issues

Here’s how wiring affects common problems:

- Entire String Dead: Likely a power supply or plug issue. If it’s a series string, one failed LED could be the culprit.

- Part of String Dark: Indicates a failed segment (in hybrid designs) or a loose connection.

- Flickering Lights: Could be a failing LED, loose wire, or incompatible power supply.

- Dim or Inconsistent Brightness: Often due to voltage drop (in series strings) or current imbalance (in parallel strings).

Pro Tip: Use a non-contact voltage tester to check for live wires before handling. For series strings, test each LED with a multimeter to find the failed one.

DIY Repairs and Modifications

Understanding the wiring helps you repair or customize your lights:

- Replacing a Failed LED: In parallel or hybrid strings, desolder the dead LED and replace it with an identical one. In series strings, ensure the replacement has the same specifications (voltage, current).

- Extending a String: Only possible with parallel or hybrid designs. Connect the new string in parallel with the existing one, matching voltage and current ratings.

- Adding Controllers: For addressable LEDs (e.g., WS2812B), ensure the controller supports parallel wiring and data protocols.

Warning: Modifying LED strings can void warranties and pose electrical risks. Always follow safety guidelines.

Data Table: Comparison of LED String Light Wiring Types

| Feature | Series Wiring | Parallel Wiring | Hybrid (Series-Parallel) |

|---|---|---|---|

| Failure Impact | Entire string fails | Only affected LED fails | Only affected segment fails |

| Voltage Requirement | High (sum of individual voltages) | Low (same as one LED) | Medium (voltage per segment) |

| Current Draw | Low (same as one LED) | High (sum of individual currents) | Medium (current per segment) |

| Brightness Consistency | High (same current) | Medium (depends on resistors) | High (within segments) |

| Manufacturing Cost | Low | High | Medium |

| Common Use Cases | Battery-powered fairy lights | Smart LED strips, high-reliability displays | Commercial and holiday lights |

Conclusion: Making the Right Choice for Your Needs

The question “Are LED string lights parallel or series?” doesn’t have a one-size-fits-all answer. Most modern LED strings use hybrid series-parallel designs to balance reliability, efficiency, and cost. Pure series wiring is rare and generally limited to low-cost, low-reliability applications, while pure parallel wiring is reserved for high-end or specialty lights.

When choosing LED string lights, consider the following:

- For Decorative or Holiday Use: Opt for hybrid designs. They offer a good mix of reliability and brightness, and segment failures are easier to manage.

- For Smart or Programmable Lighting: Choose fully parallel, addressable strings (e.g., RGBIC or NeoPixel) for maximum control.

- For DIY Projects: Understand the wiring type before modifying or extending the lights. Always prioritize safety.

By understanding the electrical principles behind LED string lights, you can make informed decisions, troubleshoot issues effectively, and even create custom lighting solutions. Whether you’re wrapping a tree, accenting a room, or building a smart home setup, the right wiring knowledge ensures your lights shine bright—year after year.

Frequently Asked Questions

Are LED string lights wired in parallel or series?

Most modern LED string lights use a parallel circuit design. This ensures that if one LED fails, the rest remain lit, improving reliability and longevity.

What happens if one LED goes out in a parallel vs. series string light?

In parallel LED string lights, a single failed bulb won’t affect others. In series circuits, the entire string may go dark due to the break in the circuit path.

Can I cut or shorten parallel LED string lights?

Yes, many parallel LED string lights can be safely cut at designated points. Series lights typically can’t be modified without disrupting the entire circuit.

Why do some LED string lights still work when a bulb is removed?

This is a hallmark of parallel wiring—each bulb operates independently. Series lights would fail entirely if a bulb is removed or burns out.

Are parallel LED string lights more energy-efficient than series?

Parallel designs often consume slightly more power due to independent paths, but they offer better performance and durability. Efficiency depends on the overall build quality, not just wiring type.

Which type lasts longer: parallel or series LED string lights?

Parallel LED string lights usually last longer because they’re less prone to total failure and handle voltage fluctuations better. Series lights are more vulnerable to cascading outages.